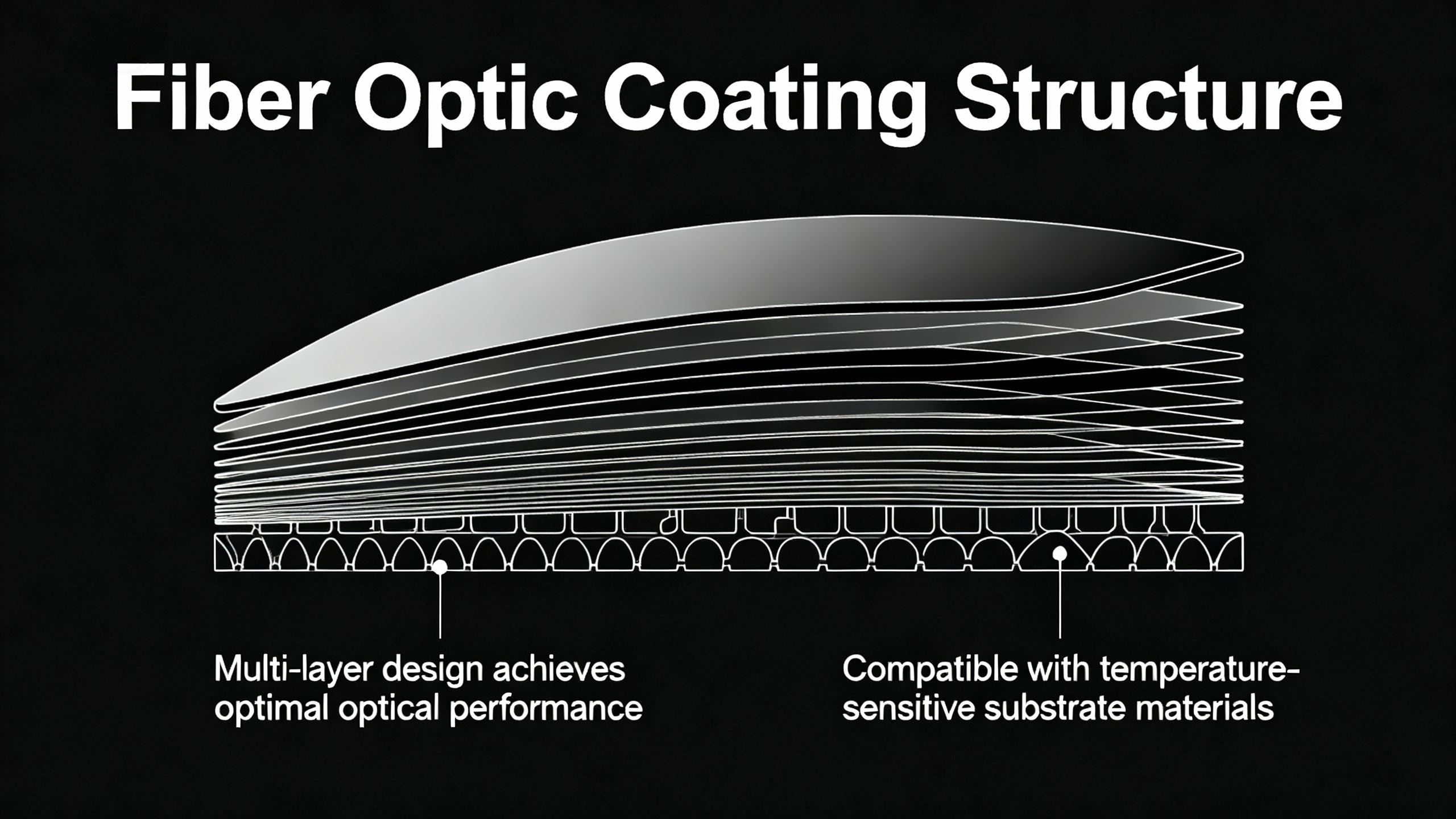

Jingseyewear leads the optical industry with cutting-edge plastic and polymer optical technology, specifically engineered for high-performance optical lenses and sunglasses. Our advanced low-temperature processes enable precise thin-film coatings on temperature-sensitive polymer materials.

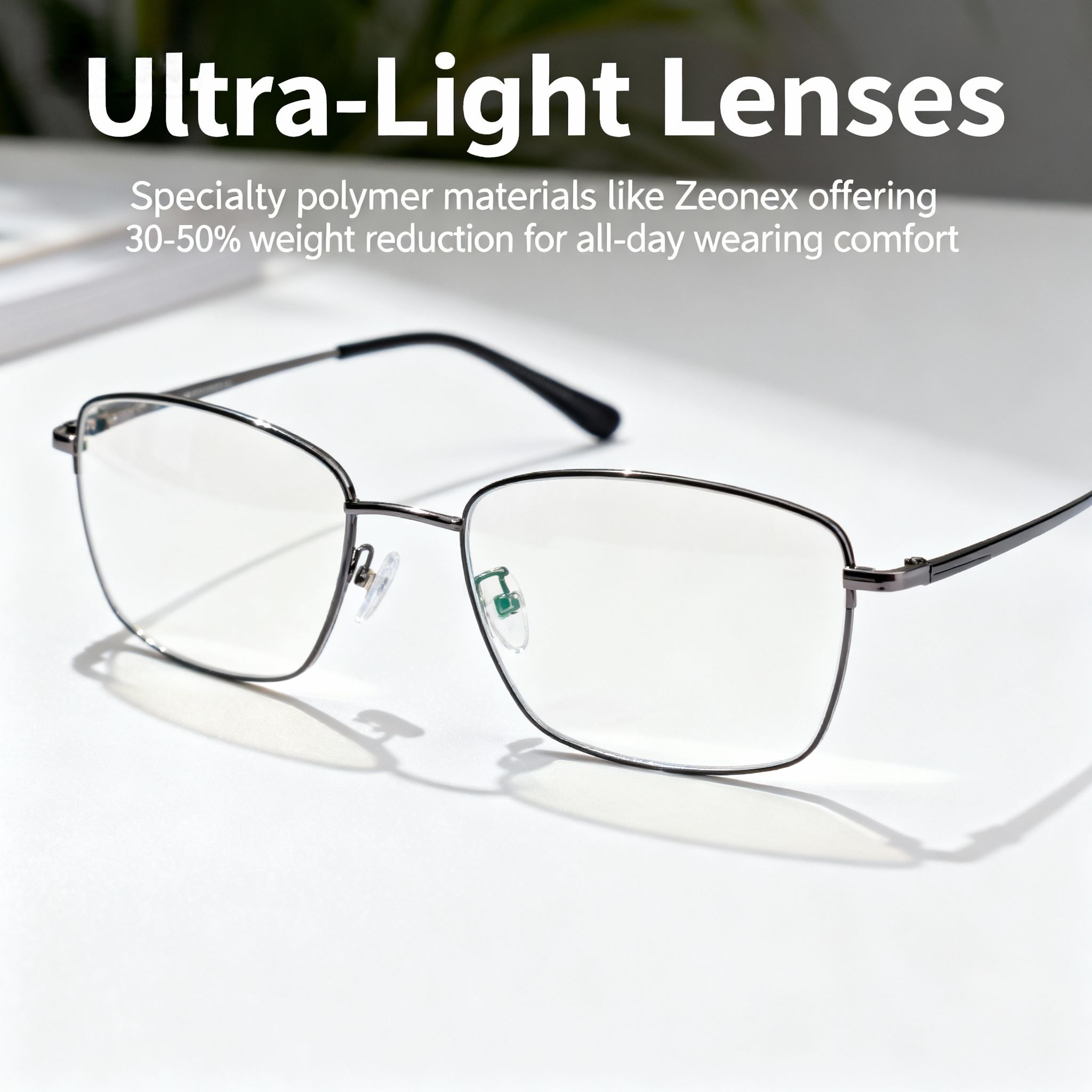

Utilizing state-of-the-art manufacturing techniques, Jingseyewear offers a comprehensive range of polymer optical solutions including acrylics, polycarbonates, polystyrenes, and specialty materials like Zeonex®. Our expert team handles complex shapes and designs while maintaining exceptional optical clarity and performance.

-------------- Technical Specifications ---------------

| Performance Parameter | Specification | Unit | Eyewear Application |

|---|---|---|---|

| Processing Temperature | < 50 | °C | Thermal Protection |

| Wavelength Range | 300 - 2000 | nm | Broadband Optics |

| Refractive Index Range | 1.47 - 1.65 | nD | Prescription Lenses |

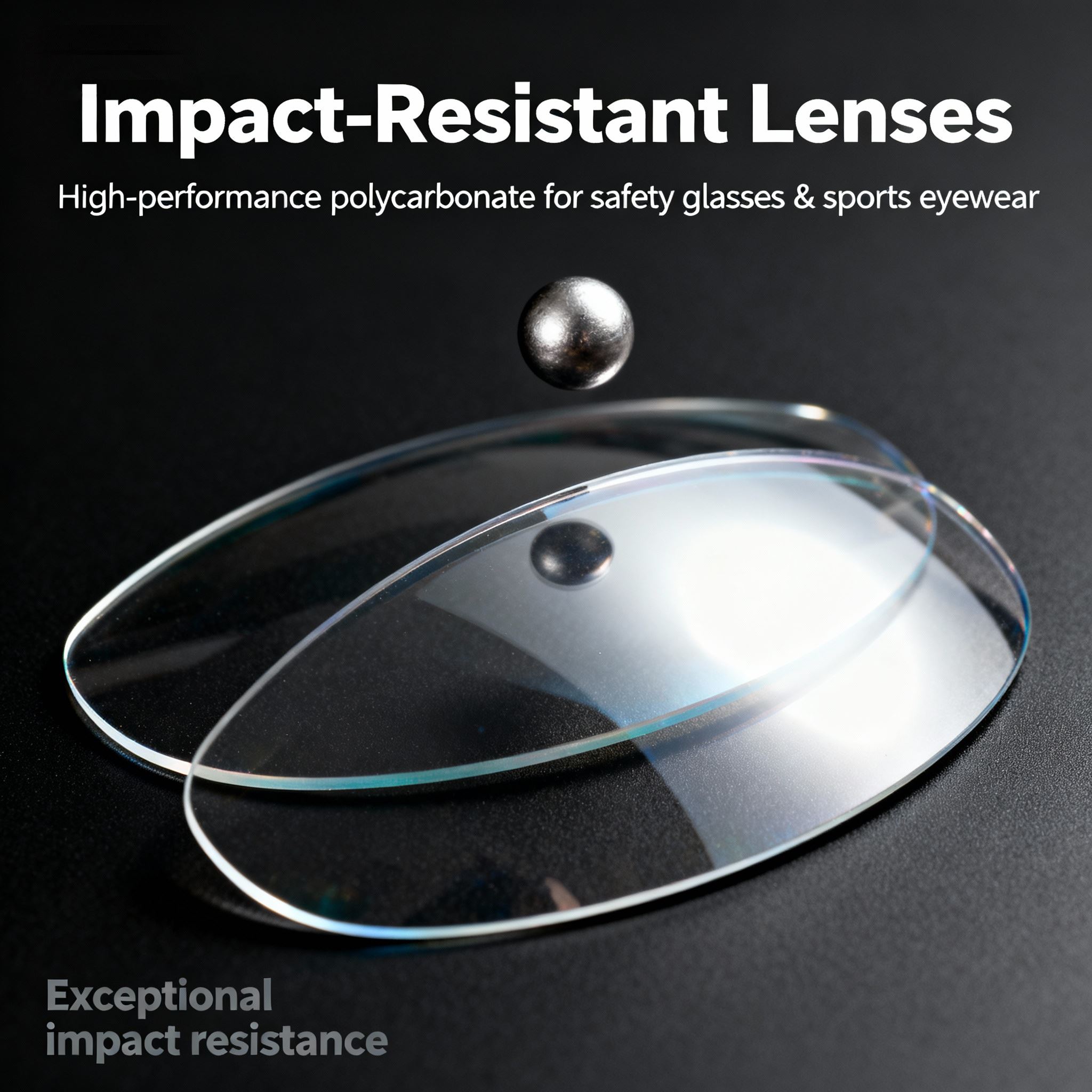

| Impact Resistance | High | Rating | Safety Lenses |

| Weight Reduction | 30-50 | % | Comfortable Wear |

-------------- Polymer Material Types ---------------

| Material Type | Refractive Index | Density | Key Features | Eyewear Application |

|---|---|---|---|---|

| Polycarbonate | 1.586 | 1.20 | Impact resistant | Safety Lenses |

| Acrylic | 1.491 | 1.19 | Optical clarity | Fashion Eyewear |

| Zeonex® | 1.522 | 1.01 | Ultra-light | Premium Lenses |

| Polystyrene | 1.590 | 1.05 | Cost effective | Economy Lenses |

-------------- Coating Technology Options ---------------

| Coating Type | Wavelength Range | Performance | Eyewear Application |

|---|---|---|---|

| Anti-Reflection | 300-2000nm | Super low AR | Prescription Lenses |

| Metal Mirrors | 300-2000nm | Enhanced | Mirror Sunglasses |

| Dielectric Mirrors | 300-2000nm | Low temp | Specialty Optics |

| Transparent Conductive | 300-2000nm | Anti-static | Smart Eyewear |

-------------- Product Categories ---------------

-------------- Military Standards Compliance ---------------

| Military Standard | Specification | Application | Benefit |

|---|---|---|---|

| MIL-M-13508C | Metal Mirrors | Mirror Coatings | Military Grade |

| ANSI Z87.1 | Impact Resistance | Safety Lenses | Safety Standard |

-------------- Eyewear Applications ---------------

Jingseyewear Polymer Optics Applications

Sports Eyewear

Sports Eyewear

Fashion Eyewear

Fashion Eyewear

Safety Glasses

Safety Glasses

Polymer materials offer 30-50% weight reduction compared to glass, providing all-day wearing comfort for users.

Superior impact resistance makes polymer lenses ideal for safety applications and sports eyewear.

Custom molding capabilities allow for complex shapes, unique designs, and creative eyewear solutions.

Discover how our advanced polymer optical technology can enhance your eyewear products

-------------- Technical Diagrams ---------------

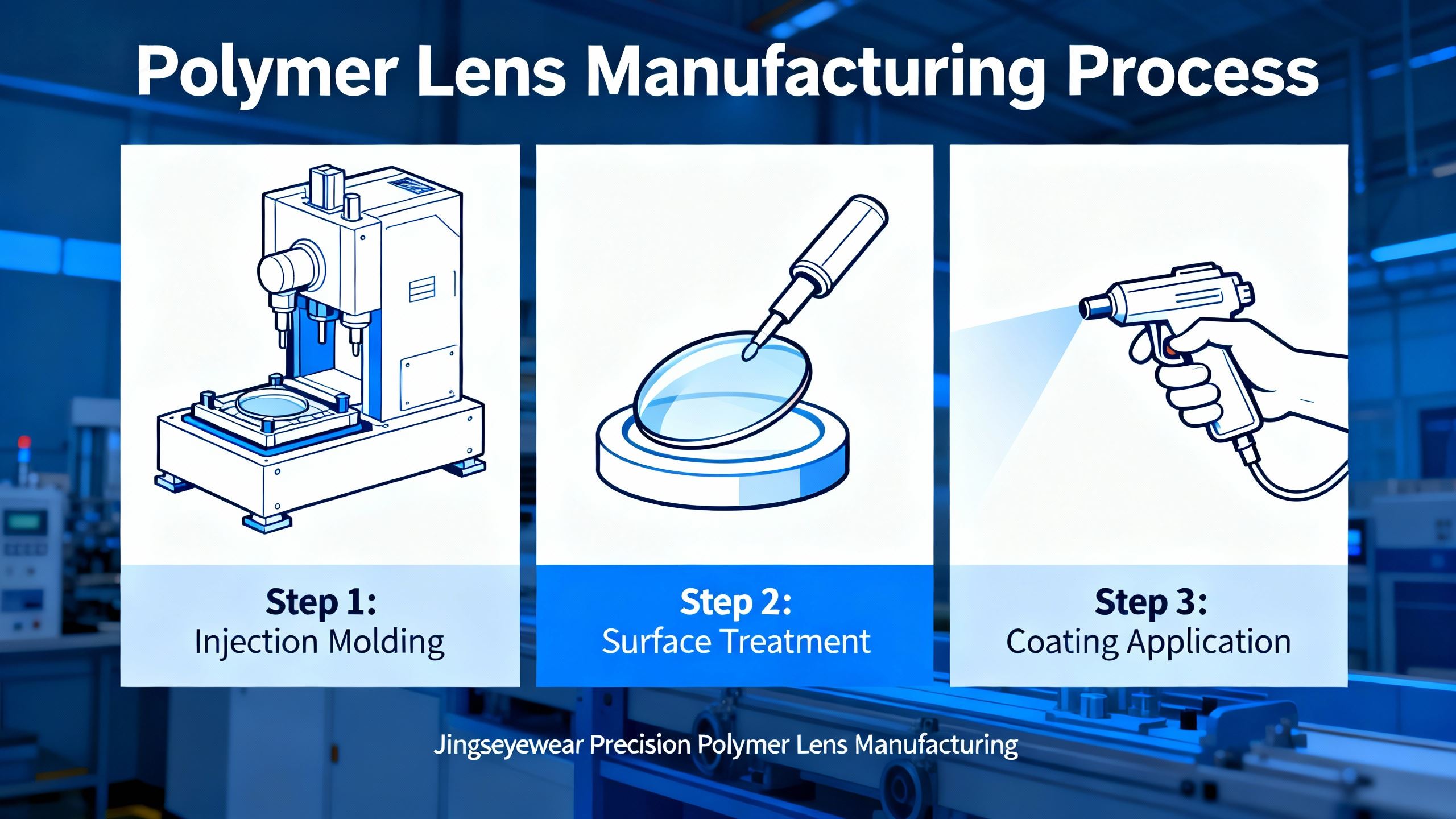

This diagram illustrates Jingseyewear's precision polymer lens manufacturing process, showing the injection molding, surface treatment, and coating application steps. Each stage is carefully controlled to ensure optical clarity, dimensional accuracy, and consistent performance.

Cross-sectional view of Jingseyewear's advanced low-temperature coating process on polymer substrates, showing how thin films are applied at temperatures below 50°C. This revolutionary technique protects the polymer material while achieving exceptional coating adhesion and optical performance.

Copyright @ 2026 Xiamen Jings Eyewear Co., Ltd. All Rights Reserved.

Network Supported

Network Supported