Full-Service Manufacturing

From raw materials to finished products — complete sunglasses, optical frames, and sports eyewear manufacturing with in-house production lines, custom branding, and sustainable material options.

15+

Years Experience

500K+

Monthly Capacity

50+

Countries Served

100%

Vertical Integration

Our vertically integrated facility houses multiple specialized production lines, each equipped with advanced machinery to handle different materials and processes. This complete in-house capability ensures quality control at every step and eliminates delays from outsourcing.

Our injection molding facility produces high-volume plastic components with exceptional precision. Ideal for TR-90, nylon, and other thermoplastic materials that require complex geometries and consistent repeatability.

Our multi-axis CNC machines cut and shape frames from solid sheet materials with micron-level precision. This process is essential for acetate, wood, bamboo, and other sheet-form materials where intricate details and smooth finishes are critical.

See Our Bamboo & Wood CNC Cutting in Action:

5-Axis

CNC Machines

0.01mm

Cutting Precision

24/7

Production Capability

Our complete metal processing facility handles everything from wire forming to final assembly. Multiple specialized stations work in sequence to transform raw metal into precision eyewear components with consistent quality.

Step 1

Wire Cutting

Step 2

Forming & Bending

Step 3

Welding

Step 4

Polishing

Step 5

Plating

Step 6

Assembly

| Material | Characteristics | Best For |

|---|---|---|

| Titanium | Ultra-light, hypoallergenic, corrosion-resistant | Premium and medical-grade frames |

| Stainless Steel | Durable, affordable, good strength | Mid-range fashion frames |

| Monel | Flexible, easy to adjust, economical | Value-focused collections |

| Beta Titanium | Superior flexibility, memory retention | Rimless and semi-rimless designs |

Surface quality separates premium eyewear from ordinary products. Our polishing lines use both automated drum tumbling and skilled hand polishing to achieve mirror-smooth finishes that feel as good as they look.

Watch Our Acetate Drum Polishing Process:

Automated polishing using rotating drums with polishing media. Efficient for high-volume acetate frame processing.

Skilled craftsmen use felt wheels and polishing compounds for final finishing and detail work on premium frames.

Our fully automated spray painting system delivers consistent, durable color finishes across high volumes. Computer-controlled spraying ensures uniform coverage while minimizing waste and environmental impact.

See Our Automated Spray Painting System:

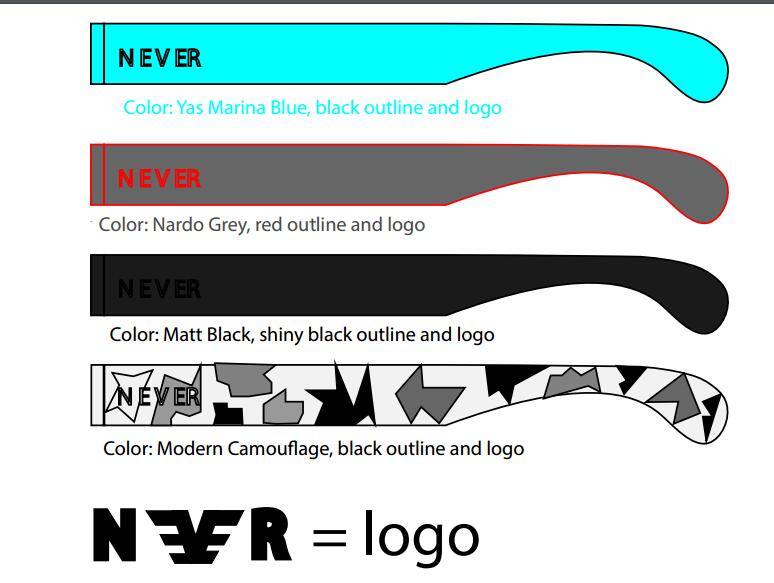

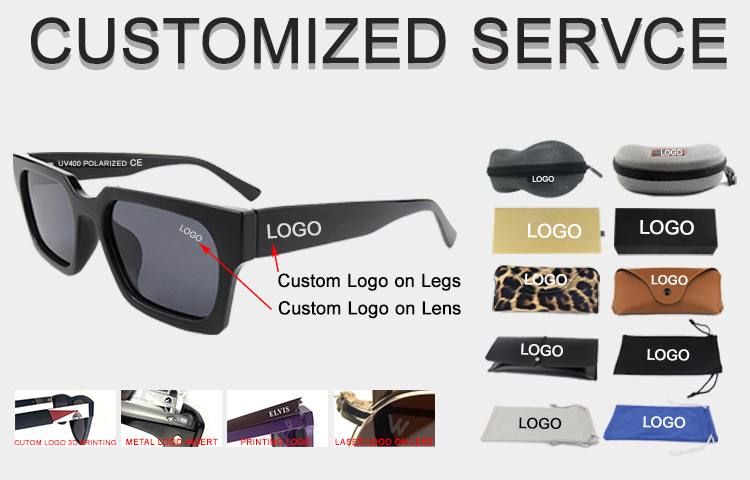

Your brand identity matters. We offer multiple logo application methods to match your design requirements, material types, and brand positioning. From subtle elegance to bold statements, we have the technique for your vision.

Permanent, precise marking for metal and acetate. Clean, professional look with excellent durability.

Multi-color logos on curved surfaces. Ideal for temples and detailed graphics.

Premium metal logo pieces embedded into frames. Luxury brand positioning.

Foil transfer for metallic and colored logos. Cost-effective for medium volumes.

Full-color digital printing with UV-cured inks. Great for complex graphics and photos.

Raised or recessed impressions for tactile branding. Subtle and sophisticated.

Complete your brand experience with custom packaging. From initial concept design to final production, we handle the entire packaging process in-house. Your products arrive retail-ready with packaging that reinforces your brand value.

1

Design Consultation

2

Concept & Mockup

3

Sample Approval

4

Mass Production

We're committed to supporting brands that prioritize environmental responsibility. Our facility offers a growing range of sustainable material options, from recycled plastics to natural fibers, helping you meet both consumer demand and regulatory requirements for eco-conscious products.

Watch Our Sustainable Materials in Action:

Certification Support: We provide documentation and traceability for sustainable materials to support your brand's environmental claims and certifications including GRS (Global Recycled Standard) and FSC.

Share your product concept, target market, and requirements. We'll discuss feasibility and provide initial guidance.

Technical drawings, material selection, and detailed pricing. Clear specifications before moving forward.

Physical prototypes for your approval. Refine fit, finish, and details until perfect.

Mass production with QC inspections. Products, packaging, and documentation shipped together.

| Minimum Order Quantity (MOQ) | 300 pieces per model/color (negotiable for first orders) |

| Sample Lead Time | 7-15 business days depending on complexity |

| Production Lead Time | 30-45 days after sample approval |

| Quality Standards | ISO 9001, CE, FDA, EN ISO 12870 |

| Payment Terms | 30% deposit, 70% before shipment (T/T, L/C accepted) |

| Shipping Options | Sea freight, air freight, express courier (DHL/FedEx/UPS) |

From concept to delivery, we're your complete manufacturing partner. Let's discuss your requirements and create something great together.

Request a QuoteHave questions about our manufacturing capabilities? Ask AI for instant insights:

Ask AI About This PageServices: OEM Manufacturing | Custom Branding | Packaging | Sustainable Materials

Last Updated: 2025

Copyright @ 2026 Xiamen Jings Eyewear Co., Ltd. All Rights Reserved.

Network Supported

Network Supported